Skim Coats can be applied to concrete light weight concrete blockwork and rendered surface. Crocodile Skim Coat Smooth is a skim coat for thin layer 03-3 mm of cementitious plaster which is Skimmed.

If you have cracking in a wall you can bet the blockwork has cracked behind if a ceiling.

Skim blockwork. Wallboard and skim coat Lath and plaster Traditional lime plaster Traditional lath plaster ceiling Plasterboard on timber stud Plastered brick 102 2 x 13mm Plastered medium density block Corrugated Sheet Sheet Expanded sheet Beam and block 50 mm topping Hollowcore plank Hollowcore plank Hollowcore plank Solid plank plus 50 mm topping. Moving blockwork walls is no mean feat causing major disruption and harder to co-ordinate building works needing several trades on site. Ion May 2018 Page 2 Section 33 New Zealand Concrete Masonry Association Inc.

Blockwork and rendered surfaces. Pros - Strong finish always get a good fixing. How the hell do they expect the skim not to crack when something moves such as timber twisting or settlement in blockwork.

Apply the render with a steel plastering trowel using a firm hand to press and ensure it sticks to the damp wall. 232010 why do people blame the skim or plasterers are they thick. Cons - Takes longer more materials required.

The high suction of certain backgrounds can be suitably adjusted by sprinkling with water. Foam the gap not too much though and just hardwall away. Thistle MultiFinish is the most popular universal skim finish plaster for common backgrounds.

The method of skimming entails plastering with a layer of thin coat and is usually applied to a wall with existing plaster in order to smooth the surface area. Applied very thinly onto interior and exterior of plustered and concrete surfaces. Contemporary design often requires flexibility in future proofing the building use and many designers therefore opt for non-loadbearing internal walls which are in essence room dividers that can be easily altered or removed at a later stage.

Add correct quantity of clean water to a bag of Skim Coat 2. Brickwork blockwork The surface must be clean dry and suitable to receive. Each pass on the hardening plaster should see more and more trowel marks and bumps disappearing.

Sand and cement renderscratch coat followed by a plaster finish. Exception of skimming with Thistle Uni-Finish the use of ThistleBond-it is recommended for smooth backgrounds whilst Thistle GypPrime is recommended for very high suction backgrounds. The first coat of render should be a very thin coat of about 5mm thick.

The plaster is not a magic compound which will hold everything together. This coat is pushed well into the wall. The downsides of wet plastering are that it takes much longer to dry than a skim coat on plasterboard plus it can be prone to cracking.

Known by BS 8212 1995 Code of practice for Drylining and Partitioning using Gypsum Plasterboard and BS 8000 Part 8 1994 Workmanship on building sites - Code of practice for. 392021 A cement render or gypsum backing known as a scratch coat is first trowelled directly onto blockwork before this is finished with a thin skim coat. Mix thoroughly with a mechanical stirrer into a.

The process involves applying a layer of cement over the concrete block wall to cover grout lines or stains and give the surface a smooth appearance. Use a good 70mm architrave and you wont have to worry about it. 1262015 Skim coating can freshen up old concrete blocks and give your home or a wall on your property a new look.

When the plaster is almost fully hard your final pass will trowel it to a lovely flat finish. Its flexibility also makes it an ideal choice for small repair jobs and patching. 782009 whip the door liner out remove the 3x2.

Skimming or skim plastering can be seen as one method used to plaster a wall. New Zealand Concrete Masonry Manual rodding or by using a 25 mm pencil vibrator. Refit the door liner centrally in the hole using 1 12.

Pros - Its quick and less time consuming plus cheaper. It is the timing that is really important in top coat plastering or skimming as it is known. MASONRY - LIGHTWEIGHT AGGREGATE BLOCKWORK Saint-Gobain Isover RD Party Wall Roll - 100mm min cavity - gypsum-based board Lightweight aggregate blocks.

BS EN 13964-2014 is the recently published current definitive standard for the manufacture and installation of suspended systems. Dot and dab the walls with plasterboard with a plastered finish. Amix Skim Coat is a premixed cement base skim coat plaster for walls and ceilinglt is formulated to provide you the most cost effective and finest surface you desire.

It can be used as part of a two-coat plaster system or on plasterboard. Packers behind the fixings.

How To Install Shelves On A Brick Or Concrete Wall Hunker Concrete Blocks Concrete Block Walls Cinder Block Walls

How To Install Shelves On A Brick Or Concrete Wall Hunker Concrete Blocks Concrete Block Walls Cinder Block Walls

Introduction To Beam And Block Floors Construction Detailing And Selection Beams Framing Construction Flooring

Introduction To Beam And Block Floors Construction Detailing And Selection Beams Framing Construction Flooring

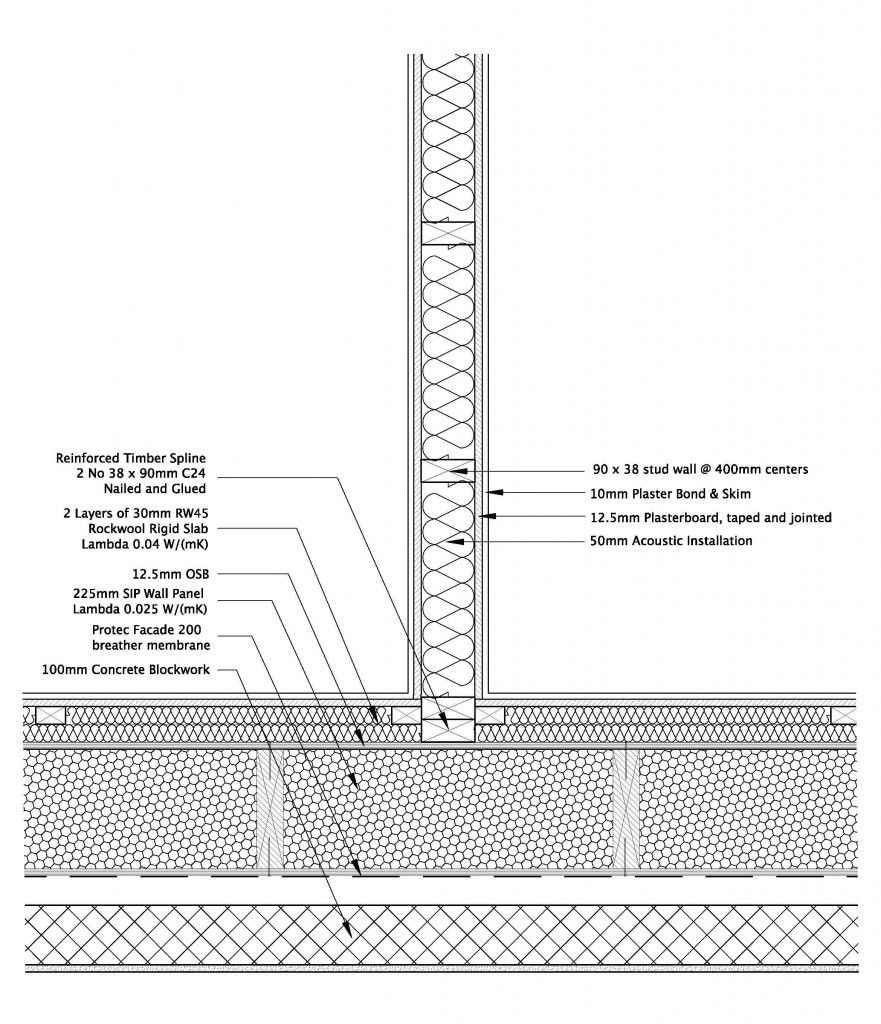

Diary Entry No 13 The Timber Frame Construction Timber Frame Construction Plasterboard Wall Wall Section Detail

Diary Entry No 13 The Timber Frame Construction Timber Frame Construction Plasterboard Wall Wall Section Detail

Deckover Concrete Block Wall Before And After Comparison Cinder Block Walls Concrete Block Walls Cinder Block Paint

Deckover Concrete Block Wall Before And After Comparison Cinder Block Walls Concrete Block Walls Cinder Block Paint

Cladding The Jerwood Gallery Hastings By Hat Projects Cladding Zinc Cladding Gallery

Cladding The Jerwood Gallery Hastings By Hat Projects Cladding Zinc Cladding Gallery

Floor Plans Construction Detail

Floor Plans Construction Detail

Building A Cinder Block Shed Diy Pdf Plans Download Build A Workshop Brick Shed Shed Building Plans Concrete Sheds

Building A Cinder Block Shed Diy Pdf Plans Download Build A Workshop Brick Shed Shed Building Plans Concrete Sheds

Detail Post Floor Details First In Architecture Interior Architecture Design Architecture Civil Engineering Design

Detail Post Floor Details First In Architecture Interior Architecture Design Architecture Civil Engineering Design

How To Lay Brick Columns And Soldier Courses Youtube Brick Columns Brick Pillars Brick Laying

How To Lay Brick Columns And Soldier Courses Youtube Brick Columns Brick Pillars Brick Laying